Organically integrate high-tech means such as cloud computing, big data, the Internet of Things, virtual reality, and artificial intelligence with the planning, design, construction, safety supervision, operation and maintenance processes of wind power enterprises, and build a smart wind power control platform that covers the entire level, business, and process of the enterprise.

01. Scientifically Formulate Wind Power Project Construction Plans

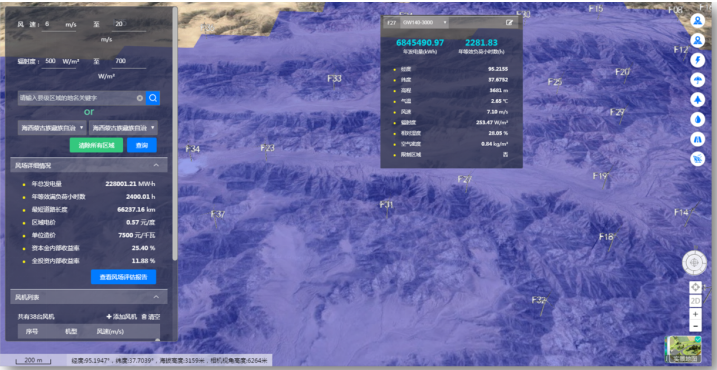

Intelligent Macro-site Selection and Turbine Layout Algorithm

Integrating wind resources with meteorological, geographic spatial characteristics and wind turbine operational data, relying on visualization tools and internal macro-site selection structural algorithms, to achieve intelligent wind farm site recommendation, automatic avoidance of restrictive factors, and utilizing optimization algorithm models to complete automatic turbine layout with visual presentation.

Pre-set wind speed and radiation parameters, automatically screen and recommend wind farm areas based on administrative regions

Turbine Selection Optimization and Efficient Layout Design

Combining multiple factors and calculation evaluation methods to optimize wind turbine selection design, matching optimal turbine and tower selections, achieving optimal point selection and full-field turbine layout design, efficiently and intensively utilizing resources to reduce wind farm construction costs, improve turbine utilization rate and wind farm benefits.

Manual + Automatic Combination: Automatically arrange turbines based on turbine layout models, manually modify turbine models and positions

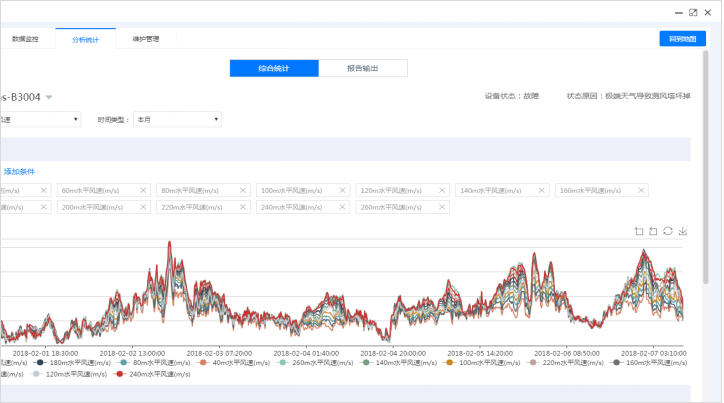

High-Precision Wind Resource Collection and Evaluation Analysis

Providing refined wind measurement services to achieve real-time collection and monitoring of wind measurement data, quickly locking in advantageous resource areas, and through high-precision short-term and medium-to-long-term meteorological predictions and trend analysis of wind resources, providing accurate data input for resource assessment, improving the accuracy and effectiveness of resource assessment results, and maximizing wind farm operational benefits.

Dynamic wind measurement data collection and trend analysis, calculation and evaluation

Investment Plan Evaluation and Optimal Selection

Providing intelligent calculation tools for wind farm investment returns to automatically calculate wind power plan returns, and supporting economic benefit comparisons of multiple plans from dimensions such as optimal levelized cost of electricity and optimal return on equity, assisting in optimal plan formulation.

Automatic收益 calculation and optimal plan comparison evaluation

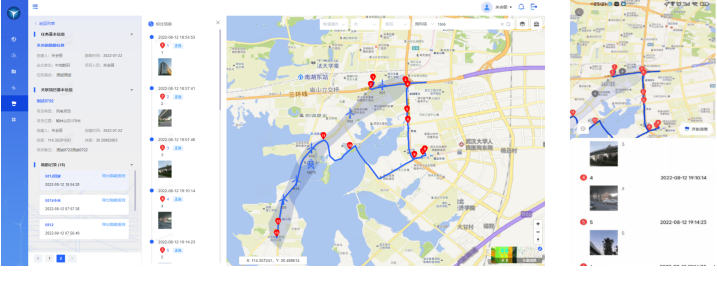

Field Survey and Plan Design Planning

Providing wind farm survey application tools to collect and annotate facilities, terrain, roads, and environment around wind farms, providing more realistic data support for refined project plan design. Supporting scene map annotation, plan design, survey report generation, and export functions.

Map annotation, drawing and plan design

02. Strictly Control Project Review Process, Standardize Project Management

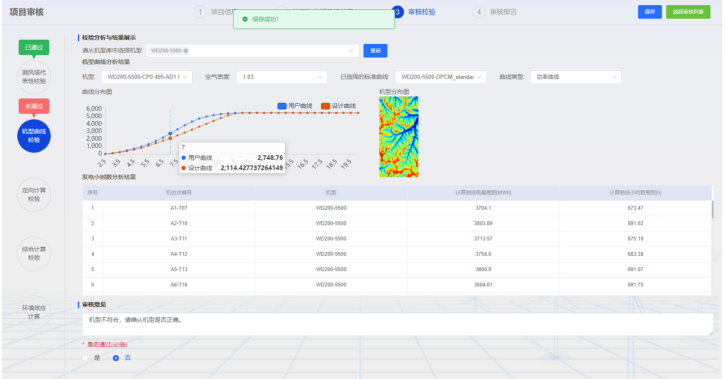

Wind Farm Design Evaluation and Review

Improving project process monitoring and standardizing project review procedures, providing convenient and transparent service support for wind farm design evaluation and detailed inspection review. By connecting with enterprise internal professional platforms to obtain project node data, combined with calculation models to achieve automated and visual output presentation of project meteorological tower representativeness, turbine curve, directional calculation, comprehensive calculation, environmental effects of noise-related projects and other detailed inspection results, conducting evaluation and review.

Project detail inspection, combined with inspection results for review

Data Collection and Standardized Management

Standardizing wind power project implementation and improving wind power project quality levels. Creating a data repository, standardizing project data directories according to project data management requirements, classifying and managing various types of data formed at each stage of the project lifecycle, facilitating queries, and maintaining traceable records.

Multi-party Online Collaborative Office

Supporting PC and mobile project collaborative office work, supporting multi-party online communication among project implementers, investors, suppliers, etc., supporting text, voice, video, and attachment sending for instant communication.

03. Wind Farm Operation Monitoring and O&M Management

Wind Farm Digital Twin Visualization

Based on digital twins, integrating comprehensive applications of advanced technologies such as GIS, big data, IoT, and mobile applications, using 3D equipment models and 3D geographic information models as the foundation to build a panoramic 3D digital twin scene of the wind farm, achieving visual presentation of wind farm surrounding environment, spatial location, and layout, truly reproducing real wind power generation scenarios. Providing first-person perspective roaming or drone perspective roaming modes to simulate patrol processes within the wind farm, bringing immersive experiences.

Wind Farm Operation Visual Monitoring

Using data integration technology to integrate and restructure data from multiple systems, presenting complex and abstract data such as project overview, real-time indicators, turbine status, environmental parameters, power generation statistics, and energy conservation and emission reduction through rich charts, graphics, and design elements to achieve centralized control. Through fusion analysis of historical data, achieving optimized resource allocation and intelligent management.

Visual wind farm operation supervision with real-time dynamic data presentation

Intelligent Equipment O&M and Inspection

Collecting and monitoring data from wind turbines and station operation monitoring equipment, providing comprehensive functions for operational data viewing, alarm reminders, and report analysis, enabling intuitive, dynamic, and comprehensive grasp of real-time data of turbines under the station, providing decision-making basis for equipment operation analysis, equipment problem identification, and operational benefit improvement.

Accurate equipment failure early warning, capable of quickly completing intelligent equipment fault diagnosis, clarifying fault causes, providing troubleshooting suggestions, intelligent work order dispatching and feedback, ensuring the openness, standardization, and safety of O&M and inspection work.

Related Software

Smart City

- Smart City Spatiotemporal Big Data Platform

- MapGIS Smart Thermal Solution

- Smart Emergency Command Platform

- MapGIS Field Work Order Solution

- Enterprise One Picture Solution

- Smart Security Combat Platform

- MapGIS Pipeline GIS Solution

- Smart Chemical Industrial Park Solution

- Smart Patrol and Prevention Platform

- MapGIS Integrated Management System Solution for Underground Municipal Facilitie

Natural Resources

- National Land Space Basic Information Platform: Smart Hub

- National Spatial Planning Implementation Monitoring Network (CSPON)

- Real estate convenience service system

- Realistic 3D Solution

- Natural Resource Asset Management Solution

- One code land management solution

- Ocean monitoring solutions

- Intelligent Disaster Management Solution

- Integrated solution for natural resources e-government

- Land survey solution

Smart Geology

- MapGIS Digital Twin Watershed Solution

- MapGIS Groundwater Informatization Solution

- MapGIS Iterative Geological Modeling Tool

- Geological Informationization Solution

- MapGIS Geological Data Management and Display System

- MapGIS Field Data Collection System

- MapGIS Smart Environmental Protection Solution

- Integrated solution for urban geology above ground and underground

- Geological big data cloud platform

- MapGIS Mining Management and Modeling System

More Applications

- Series solutions for the communication industry

- MapGIS CIM Underground Space Platform

- Smart wind power solution

- Solution for Radio and Television Resource Management

- Transportation Meteorological Support Service Solution

- High performance processing solution for remote sensing images

- Multi source remote sensing data management solution

- Solution for Multi source Meteorological Information Integration Application and Service Platform

- Solution for Visualization Platform of Meteorological 3D Storm Body Echo Data

- Solution for Weather Radar Construction Business Platform